Perylene pigment black 32 Perylene black 32 NIR reflective pigment

Perylene Black 32 ( Paliogen Black L0086)

C.I.NO.: 71133

[Molecular Formula] C40H26N2O6

[Structure]

[Molecular Weight] 630.64

[CAS No] 83524-75-8

diisoquinoline-1,3,8,10(2H,9H)-tetrone

[Specification]

Appearance: Black powder with green light Heat Stability: 280℃

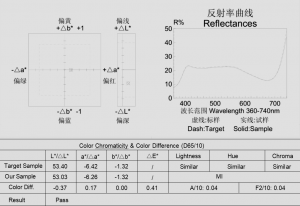

Tinting Strength %: 100±5 Shade: Similar to standard sample

Moisture %:≤1.0 Solid Content: ≥99.00%

Application: Varnish, paint, coating, plastic etcAdvantages:

Provide yellowish and bluish black shade

Very high heat resistance up to 280 ℃

Very good light and weather fastness 8

Material quality is well recognized by customers.

[ARCD]

Product Description

Pigment Black 32 is a flagship perylene-based organic black pigment that combines high infrared reflectivity with exceptional stability. Its greenish-black hue and semi-transparency in coatings provide deep blackness while allowing infrared transparency, outperforming conventional inorganic IR-reflective pigments in thermal management.

Key physicochemical properties include a density of 1.48 g/cm³, oil absorption of 35–45 g/100g, pH 6–10, and moisture content ≤0.5%3610. Its chemical resistance covers acids (2% HCl), alkalis (2% NaOH), ethanol, and petroleum solvents, rated at grades 4–5 (5 being optimal). It adapts to water-based, solvent-borne, baking, and powder coatings, and exhibits excellent compatibility with plastics (e.g., in-situ polyester polymerization), preventing carbon precipitation issues

| Industry | Use Case | Performance Requirement |

|---|---|---|

| Automotive | OEM coatings, Trim components | UV resistance, Thermal cycling |

| Industrial Coatings | Agricultural machinery, Pipe coatings | Chemical exposure, Abrasion resistance |

| Engineering Plastics | Connectors, Automotive interiors | Injection molding stability |

| Printing Inks | Security inks, Packaging | Metamerism control, Rub resistance |

Applications

- Infrared-Reflective & Thermal Insulation Coatings:

Used in building facades and industrial equipment coatings to reflect NIR radiation (>45% reflectivity over white substrates), reducing surface temperatures and energy consumption. - Automotive Paints:

High-end OEM finishes, repair coatings, and black high-reflectivity photovoltaic backsheets, balancing aesthetics with thermal management. - Military Camouflage Materials:

Utilizes IR transparency for low-thermal-signature coatings to counter infrared detection. - Plastics & Inks:

Engineering plastics (heat-resistant to 350°C), in-situ polyester fiber dyeing, and premium printing inks. - Research & Biological Fields:

Biomolecular labeling, cell staining, and dye-sensitized solar cells

Pigment Black 32 (S-1086) is an organic pigment with outstanding performance, and its excellent lightfastness and heat resistance are its core competitive advantages. The lightfastness rating of 8 makes it irreplaceable in outdoor scenarios, such as exterior wall coatings and outdoor coiled materials, which can maintain stable appearance for a long time and reduce maintenance costs. The heat resistance of 280℃ has expanded its application in high-temperature processing fields, such as the high-temperature baking process of automotive coatings and the melting stage of plastic processing, ensuring the stable performance of products during processing and use.

From the application perspective, its multi-field applicability shows strong market potential. It can meet the performance requirements of pigments in both high-tech fields such as photovoltaics and lithium batteries, and traditional industries such as automobiles and construction. The neutral pH value and good compatibility allow it to be successfully applied in different substrates and production processes, reducing the use threshold for enterprises.

Highlighting environmental characteristics will become its new competitive advantage. In general, Pigment Black 32 has strong market competitiveness due to its excellent performance and wide applicability. If it can be further improved in terms of environmental protection, its market prospect will be broader.