Driving Eco-Performance Beyond Compliance in High-Demand Applications

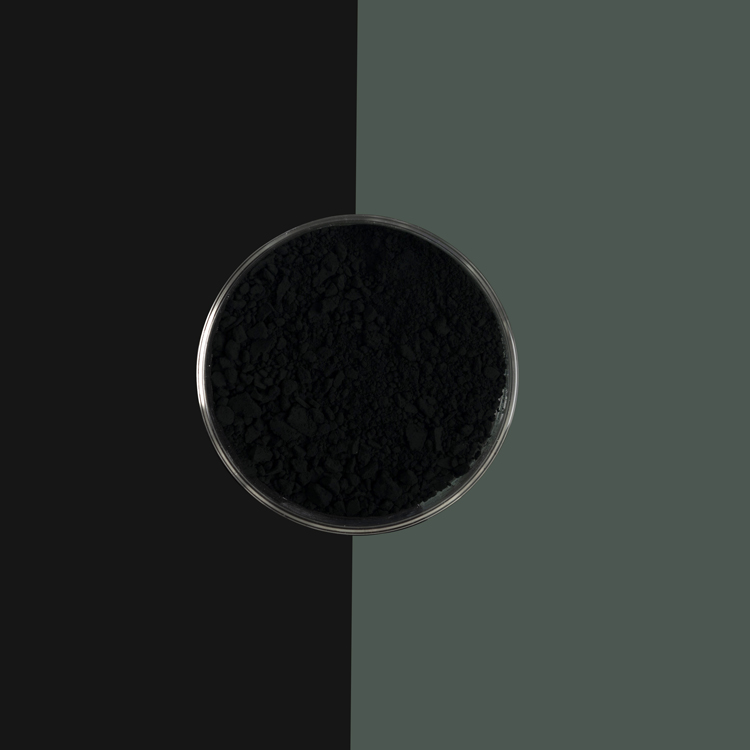

Color is the silent signature of quality and durability in modern manufacturing. From the deep, enduring blacks gracing luxury vehicles to the vibrant hues defining premium plastics and electronics, high-performance pigments like Perylene Black 32 (PBk 32) are fundamental. Yet, the legacy of pigment production often carried a heavy environmental burden. Today, driven by stringent regulations, conscious consumerism, and visionary manufacturers, the industry is transforming. Perylene Black 32 stands at the forefront of this shift, embodying how advanced chemistry delivers both superior performance and a demonstrably cleaner footprint.

Tackling Manufacturing’s Environmental Equation

The journey towards sustainable color starts where pigments are born. Traditional synthesis could be resource-heavy, relying on volatile solvents and significant energy. Forward-thinking producers of PBk 32 are revolutionizing this:

Solvent Shift: Phasing out hazardous VOCs towards greener alternatives like ionic liquids or supercritical CO₂. Where essential solvents remain, advanced closed-loop recovery systems capture, purify, and reuse >95%, slashing emissions and costs.

Energy Intelligence: Modern reactors prioritize thermal efficiency. Cutting-edge heat recovery systems capture waste energy from high-temp processes to pre-heat feedstocks or dry product, dramatically lowering the carbon footprint per kilo.

This isn’t just compliance; it’s operational excellence yielding leaner, greener PBk 32 production.

Mastering the Waste Stream: From Burden to Resource

Pigment manufacturing generates complex outputs. Leading PBk 32 suppliers treat waste not as an endpoint, but a challenge for circular solutions:

Water: Multi-stage treatment (physical/chemical, advanced biological like MBRs, final polishing with AOPs) ensures effluent meets strict discharge standards, protecting aquatic ecosystems.

Air: Regenerative Thermal Oxidizers (RTOs) destroy VOCs and process gases with >99% efficiency.

Solids: The paradigm shift is key. Filter cakes and sludges are analyzed for resource recovery – finding new life as inert fillers in construction materials (bricks, cement), diverting waste from landfill and closing the loop.

Perylene Black 32: Engineered Durability as Environmental Stewardship

Performance is sustainability. PBk 32′s intrinsic properties make it a strategic choice for eco-conscious formulators:

Unmatched Lightfastness & Weathering: Colors stay vibrant longer, significantly extending product lifespans (automotive coatings, construction materials, outdoor textiles). Less repainting/replacement = conserved resources.

Exceptional Thermal Stability: Withstands high-bake ovens and plastic extrusion without degradation, enabling efficient processing and durable end-products.

Regulatory Confidence: Engineered for low toxicity, minimal heavy metals, and low migration, ensuring compliance with REACH, RoHS, EN-71-3 (toys), FDA (indirect food contact), and global eco-labels. It’s color you can trust, safely.

Collaboration: The Keystone of Greener Value Chains

Sustainability isn’t a solo act. Leading PBk 32 suppliers act as true partners:

Transparency First: Providing comprehensive SDS, CofA, REACH dossiers, and life cycle data empowers customer compliance and reporting.

Formulation Synergy: Offering expert technical support to integrate PBk 32 optimally into low-VOC, water-based systems, helping customers meet evolving standards (e.g., automotive OEM specs, sustainable building codes).

Shared Goals: This deep collaboration amplifies the environmental benefits of PBk 32 throughout the chain – from masterbatch to molded part, coating to consumer good.

Innovating the Future: R&D Powering Next-Gen Sustainability

The commitment extends beyond today’s best practices. R&D is focused on fundamental reinvention for PBk 32 and beyond:

Bio-Based Pathways: Exploring renewable feedstocks to reduce reliance on petrochemicals.

Biocatalysis: Developing enzyme-driven syntheses for lower energy, milder conditions, and fewer by-products.

Advanced Dispersion Tech: Optimizing PBk 32 for peak performance in waterborne systems, enabling the next generation of ultra-low VOC coatings and inks.

Sustainability: The Foundation of Brand Value and Trust

For discerning buyers, a supplier’s commitment is paramount. Leading PBk 32 manufacturers embed sustainability culturally:

Certified Commitment: Pursuing and maintaining certifications like ISO 14001 (Environmental Management) and Responsible Care®.

Transparent Reporting: Openly sharing environmental performance metrics and progress.

Industry Leadership: Actively participating in forums, setting higher benchmarks, and driving collective progress. This builds the brand trust that secures long-term partnerships.

Your Partner in High-Performance, Sustainable Color

For formulators and manufacturers prioritizing longevity, compliance, and environmental responsibility, Perylene Black 32 is more than a pigment – it’s a strategic advantage. Partnering with suppliers who demonstrably lead in sustainable manufacturing and innovation, like those offering high-performance, compliant PBk 32, ensures your products meet the highest standards of quality and eco-performance that today’s market demands.

Explore how Perylene Black 32 can elevate your product line – contact us about wholesale opportunities today.

Post time: Aug-12-2025