When exposed to ultraviolet light, hidden patterns on banknotes begin to glow; car paint retains its color and luster despite years of sun and wind; sunglasses precisely filter harmful blue light—behind these everyday scenes lies a chemical enterprise’s precise mastery of light.

In the specialized field of the chemical industry, pigments and dyes are not merely “coloring agents” but key enablers of product functionality. While traditional suppliers often focus only on color itself, Topwell Chem has chosen a different path.

With over 11 years of industry expertise, this company treats “light” as its core technical language, providing solutions from the perspective of spectral management.

1.Spectral Strategy: A Technological Leap from Color to Function

Exploring Topwell Chem’s product portfolio reveals not just a pigment library, but a spectral management toolbox.

Each product is designed for specific wavelengths: UV fluorescent pigments become visible under UV light, applied in currency anti-counterfeiting and specialty coatings; thermochromic pigments change color with temperature, creating dynamic visual effects for textiles, cosmetics, and crafts.

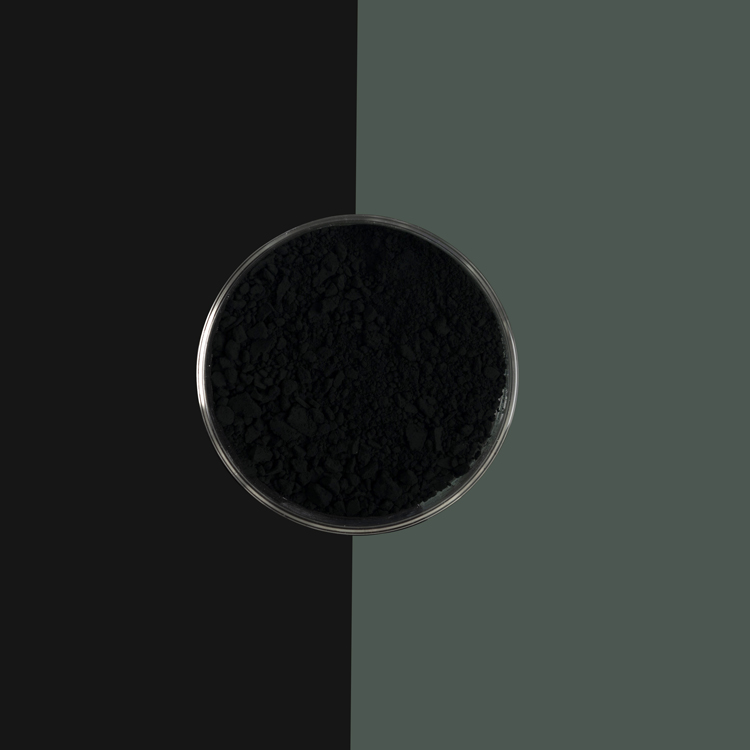

Beyond the visible spectrum, NIR-absorbing dyes serve high-tech fields such as laser protection and infrared detection. Perylene pigments, with their exceptional weather resistance, are a reliable choice for automotive finishes and industrial coatings.

The development of blue light absorbers directly addresses health concerns related to excessive blue light from electronic screens, finding applications in protective eyewear and automotive window films.

This spectral-based product strategy enables Topwell Chem to meet diverse needs—from basic coloring to cutting-edge functionality—evolving from a mere “color supplier” to an “optical performance partner.”

2. Stable Properties: A Commitment to Batch-to-Batch Consistency

In high-end manufacturing, minor deviations in material performance can lead to entire production batches being scrapped. Recognizing this, Topwell Chem has established a rigorous quality control system.

The company sets specific testing standards for different product series: purity and hue for pigments, absorption and emission wavelengths for dyes, and brightness and wavelength consistency for UV products.

Its distinctive “pre-shipment sample confirmation mechanism” further integrates customers into the quality control loop. After bulk production, customers receive randomly selected samples for final approval.

Only upon written customer confirmation is the entire batch shipped. While this process adds a step, it fundamentally eliminates the risk of specification mismatches and ensures continuity in downstream production.

3. Collaborative Ecosystem: Partnerships Beyond Transactions

Long-term collaboration is built on reliability and transparency. Topwell Chem commits to maintaining a stable long-term supply and pricing while ensuring consistent quality, helping customers control production costs.

The company’s cooperation process is clearly divided into five stages: requirement communication, solution quoting, contract signing, payment, and delivery. Each stage is supported by dedicated professionals to ensure information symmetry and smooth operations.

When customers encounter technical issues, the company recommends a quick self-check first—confirming product batch numbers, process parameters, and other basic details—followed by preparing a detailed problem description, preferably with photos or videos.

Customers can contact the technical support team via their dedicated sales manager or a unified email address. The company promises a rapid response mechanism, treating customer challenges as shared issues rather than mere complaints—an approach that fundamentally transforms traditional supplier-customer dynamics.

4. Custom Development: Turning Unique Needs into Product Reality

Beyond its standard product lines, Topwell Chem’s core strength lies in its customization capabilities. When customers present unique optical performance requirements, specific color specifications, or stability needs for particular environments, the company’s R&D team begins its creative process.

The customization journey starts with in-depth requirement discussions. Customers only need to provide detailed technical parameters or reference samples, and experienced R&D engineers can translate these into feasible chemical formulations.

This capability allows Topwell Chem to serve innovative projects that cannot find suitable materials on the open market, acting as a chemical solutions partner in customers’ product development and jointly exploring new frontiers in materials science.

An automotive manufacturer needed a specialty pigment that could maintain color stability under extreme climates—they turned to Topwell Chem.

The R&D team adjusted the molecular structure of perylene pigments to retain vibrancy even in high-temperature, high-humidity environments. After three months of joint testing, the new pigment was successfully applied to a premium vehicle series.

At the intersection of color and light, chemistry is no longer just powder in bottles—it is a bridge connecting innovative ideas to market reality.

With its profound understanding of spectroscopy, Topwell Chem is helping global customers transform more “impossible” colors and functions into tangible products, creating technical value that goes beyond vision in every application.

Post time: Jan-20-2026